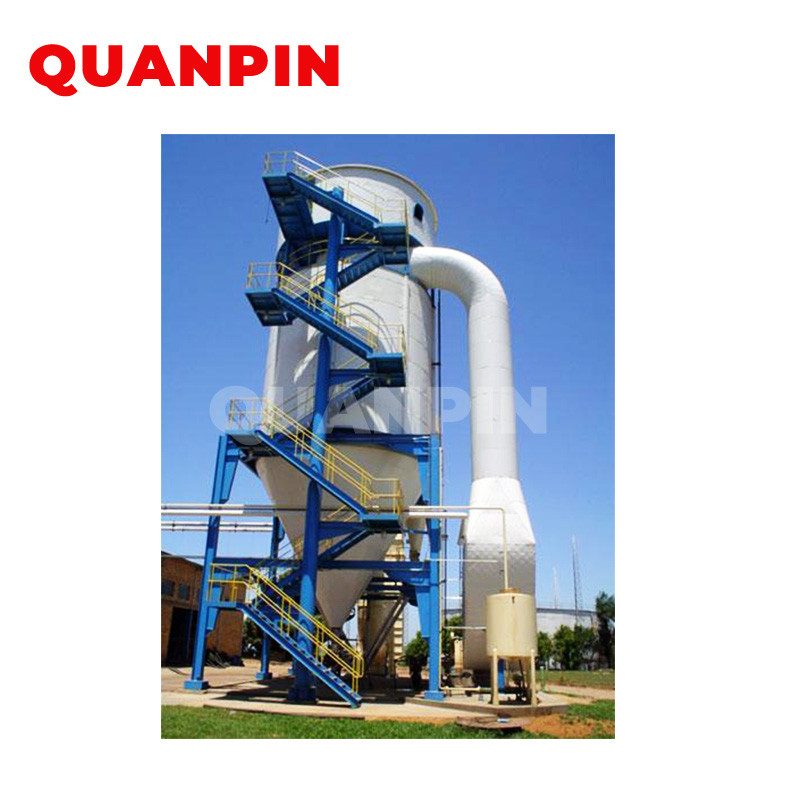

Qalajiyaha Buufinta Centrifugal Taxanaha LPG ee Xawaaraha Sare leh oo leh Qiimo Weyn

Sharaxaadaha

Qallajinta buufinta waa tignoolajiyada ugu badan ee loo isticmaalo qaabaynta tignoolajiyada dareeraha ah iyo warshadaha qalajinta. Tignoolajiyada qalajinta ayaa ugu habboon soo saarista budada adag ama walxaha walxaha ka soo baxa walxaha dareeraha ah, sida: xalka, emulsion, joojinta iyo koolada la bamgareyn karo, sababtan awgeed, marka cabbirka walxaha iyo qaybinta alaabada kama dambaysta ah, waxa ku jira biyaha haray, cufnaanta cufnaanta iyo qaabka walxaha ay tahay inay buuxiyaan heerka saxda ah, qalajinta buufinta waa mid ka mid ah tignoolajiyada ugu badan ee la doonayo.

Fiidiyowga

Mabda'a Shaqada

Qalajiyaha buufinta ee wareegga furan iyo socodka, atomization-ka centrifugal. Ka dib qalajinta hawada dhexdhexaadka ah ee dhexdhexaadka ah, shaandheeyayaasha hawada ee waxtarka dhexdhexaadka ah iyo sifeeyaha sida waafaqsan tilmaamaha hawlgalka iyadoo la adeegsanayo sawir-qaadista ka dibna lagu kululeeyo afuufaha kuleyliyaha, shaandhada waxtarka leh ee sare u marta qaybta qaybiyaha hawada kulul ee lagu buufiyo munaaradda ugu weyn. Ka dib marka walxaha dareeraha ah sida waafaqsan tilmaamaha hawlgalka ee bamka peristaltic, atomizer-ka loo geliyo wareegga xawaaraha sare, xoogga centrifugal-ka waxaa lagu kala firdhiyaa dhibco yaryar. Ku buufi qalajinta munaaradda ugu weyn iyadoo hawo kulul lagu shubayo dhibco yaryar oo si buuxda u qalajinaya iyadoo la adeegsanayo is-weydaarsiga kulaylka badeecad ku taal waddo gaar ah, ka dibna iyada oo loo marayo duufaan si loo gaaro kala-goyn, walxaha adag waa la ururiyaa, la sifeeyaa ka dibna dhexdhexaadka gaaska, ka dibna waa la sii daayaa. Ku buufi nidaamka oo dhan si fudud loo nadiifin karo, iyada oo aan lahayn dhammaadyo dhintay, iyadoo la raacayo shuruudaha GMP.

Qodobbada:

1. Taabashada dhibcaha hawada kulul: xaddi ku filan oo hawo kulul ah oo soo galaya Qolka qalajinta buufinta waa in loo tixgeliyaa jihada iyo xagasha socodka gaaska kulul, iyo ha ahaato socodka, socodka ka soo horjeeda ama socodka isku dhafan, si loo hubiyo in taabashada buuxda ee dhibicda ay noqon karto is-weydaarsi kulayl oo ku filan.

2. Buufinta: Nidaamka qalajiyaha buufinta waa inuu hubiyaa qaybinta cabbirka dhibcaha oo isku mid ah, taas oo lagama maarmaan ah. Sababtoo ah si loo hubiyo heerka gudbinta tayada badeecada.

3. Iyo xagasha xagasha koonka ee naqshadaynta dhuumaha: Waxaan ka helnaa xog la taaban karo oo ka timid soo saarista ku dhawaad kun unug oo ah kooxda qalajiyaha buufinta, waana la wadaagi karnaa.

Sifo:

1. Xawaaraha qalajinta buufinta, marka dareeraha maaddada la atom gareeyo, aagga dusha sare ayaa si weyn u kordhay, iyadoo hawada kulul ay la xiriirto habka, daqiiqaddu waxay noqon kartaa 95% -98% uumi-baxa qoyaanka, waqtiga qalajinta wuxuu noqon karaa dhowr ilbiriqsi oo keliya, gaar ahaan walxaha xasaasiga u ah kulaylka oo qalalan.

2. Badeecadu waxay leedahay isku midnimo wanaagsan, dareere iyo milmi sare, daahirnimo iyo tayo wanaagsan.

3. Habka wax soo saarka qalajiyaha buufinta waa la fududeeyay, waana la xakameyn karaa si fudud. Wixii qoyaan ah ee 40-60% (qalabka gaarka ah, ilaa 90%) dareeraha waxaa lagu qallajin karaa badeeco budo ah, ka dib marka la qalajiyo iyada oo aan la burburin oo la baarin si loo yareeyo hababka wax soo saarka, loo hagaajiyo daahirnimada badeecada. Cabbirka, cufnaanta badan, qoyaanka, gudaha xad gaar ah waxaa lagu hagaajin karaa iyadoo la beddelayo xaaladaha hawlgalka, xakamaynta iyo maaraynta aad bay ugu habboon tahay.

Halbeegga Farsamada

| Moodel/Shay | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| Heerkulka hawada ee laga galo (°C) | 140-350 Xakamaynta Tooska ah | ||||||||||||||

| Heerkulka hawada soo baxda (°C) | 80-90 | ||||||||||||||

| Habka atomization | Atomizer-ka xawaaraha sare leh ee centrifugal (gudbinta farsamada) | ||||||||||||||

| Uumi-baxa biyaha xadka sare (kg/saacaddii) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| Xawaaraha sare (rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | 11000-12000 | ||||||||

| Dhexroorka saxanka buufinta (mm) | 60 | 120 | 150 | 180-210 | Sida waafaqsan shuruudaha habka farsamada | ||||||||||

| isha kulaylka | Koronto | uumi + koronto | Uumi + koronto, saliid shidaal, gaas, shooladda qaraxa kulul | ||||||||||||

| Awoodda kuleylka korontada xadka sare (kw) | 12 | 31.5 | 60 | 81 | 99 | Isticmaalka ilo kale oo kulayl ah | |||||||||

| Cabbirka (L × W × H) (m) | 1.6 × 1.1 × 1.75 | 4 × 2.7 × 4.5 | 4.5 × 2.8 × 5.5 | 5.2 × 3.5 × 6.7 | 7×5.5×7.2 | 7.5 × 6 × 8 | 12.5 × 8 × 10 | 13.5 × 12 × 11 | 14.5 × 14 × 15 | Go'aaminta iyadoo loo eegayo xaaladda dhabta ah | |||||

| Badeecada budada ah heerka soo kabashada | Qiyaastii 95% | ||||||||||||||

Kooban

Qalajiyaha Buufinta, Munaaradda qalajinta buufinta waa habka sameynta dareeraha, warshadaha habka qalajintana waa kuwa ugu badan ee la isticmaalo. Ugu habboon soo saarista budada laga helo emulsions-ka joojinta, xalalka, emulsions-ka iyo dareeraha koollada, badeecada adag ee granular-ka ah. Sidaa darteed, marka qaybinta cabbirka walxaha ee la dhammeeyay, qoyaanka haray, cufnaanta badan iyo qaabka walxaha ay la jaanqaadaan heerka saxda ah, Qalajiyaha Buufinta ayaa ku habboon habka qalajinta.

Shaxda Socodka

Codsiga

Waxyaabaha kiimikada ah: PAC, midabyada kala firdhiya, midabyada falcelinta leh, kaaliyayaasha dabiiciga ah, silica, budada dharka lagu dhaqo, zinc sulfate, silica, sodium silicate, potassium fluoride, calcium carbonate, potassium sulfate, kaaliyayaasha aan organic ahayn, nooc kasta iyo noocyo kale oo qashin ah.

Cunto: amino acids, fiitamiinno, ukun, bur, cunto lafaha, dhir udgoon, borotiin, budada caanaha, cuntada dhiigga, burka soy, qaxwo, shaah, gulukoos, potassium sorbate, pectin, dhadhan iyo udgoon, casiir khudaar, khamiir, istaarij, iwm.

Dhoobada: Alumina, zirconia, magnesia, titania, titanium, magnesium, kaolin, dhoobo, ferrites kala duwan iyo oksaydh bir ah.

QUANPIN Qalajiyaha Granulator-ka

YANCHENG QUANPIN MACHINERY CO., LTD.

Soo-saare xirfadle ah oo diiradda saaraya cilmi-baarista, horumarinta iyo soo saarista qalabka qalajinta, qalabka granulator-ka, qalabka isku-darka, qalabka burburinta ama shaandhada.

Waqtigan xaadirka ah, alaabtayada ugu muhiimsan waxaa ka mid ah awoodda noocyada kala duwan ee qalajinta, burburinta, burburinta, isku darka, xoojinta iyo soo saarista qalabka waxay gaartaa in ka badan 1,000 oo qalab. Iyadoo leh khibrad qani ah iyo tayo adag.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Telefoonka Gacanta:+86 19850785582

WhatsApp:+8615921493205